歡迎訪問(wèn)雙象榨油機(jī)官網(wǎng)!

電話:15639480959

座機(jī):15670843637

郵箱:2765111466@qq.com

地址:河南省周口市沈丘縣北城新華大道與吉祥路交叉口西300米

6YL-68型螺旋榨油機(jī)

6YL-68型螺旋榨油機(jī)的主要性能參數(shù)

主要技術(shù)參數(shù)

(一) 榨膛直徑……………………………………………………………………………………70毫米

長(zhǎng)度……………………………………………………………………………………….200毫米

(二) 榨螺軸直徑……………………………………………………………………………….68.5毫米

長(zhǎng)度…………………………………………………………………………………………600毫米

轉(zhuǎn)數(shù)……………………………………………………………………………………137160轉(zhuǎn)/分

(三) 排骨長(zhǎng)度……………………………………………………………………………………200毫米

數(shù)量 甲型………………………………………………………………………………….8根

乙型………………………………………………………………………………….8根

(四) 榨螺軸與排骨的間隙………………………………………………………………………0.75毫米

(五) 配用動(dòng)力……………………………………………………………………………………..5.5仟瓦

轉(zhuǎn)速………………………………………………………………………………………….1440轉(zhuǎn)/分

(六) 電動(dòng)機(jī)皮帶輪直徑……………………………………………………………………..120-140毫米

(七)外形尺寸(長(zhǎng)x寬x高)…………………………………………….1000毫米x538毫米x1050毫米

(八)全機(jī)總重量…………………………………………………………………………………….140公斤

一、工作原理與構(gòu)造:

1、工作原理:

榨油機(jī)運(yùn)轉(zhuǎn)時(shí),將處理好的料胚帶如料斗,油料從料斗進(jìn)入榨膛。有榨螺的螺旋向里推進(jìn),進(jìn)行壓榨。

因料胚在榨油機(jī)的榨膛內(nèi)是在運(yùn)轉(zhuǎn)狀態(tài)下進(jìn)行的,在榨膛高壓的條件下,料胚和榨螺,榨膛之間產(chǎn)生很大的摩擦阻力。這樣就能使料胚和料胚產(chǎn)生摩擦,造成相對(duì)的運(yùn)動(dòng)。另一放面,榨螺的根圓直徑是逐漸增粗的,當(dāng)榨螺轉(zhuǎn)動(dòng)時(shí),螺紋使料胚即能向前推進(jìn)又能向外翻轉(zhuǎn),同時(shí)靠近榨螺螺紋表面的料層隨著榨軸轉(zhuǎn)動(dòng),這樣在榨膛里的每個(gè)料胚微粒都不是等速度同方向的運(yùn)動(dòng)。而在微粒之間也存在著相對(duì)的運(yùn)動(dòng)。有摩擦產(chǎn)生的熱量又滿足了榨油工藝操作上所必須的一份熱量,有助于促使料胚中的蛋白質(zhì)熱變性,破壞了膠體,增加了塑性,同時(shí)也降低了油的粘性,容易壓榨出油來(lái),因而提高了榨油機(jī)的出油率。

1. Oration principle and structure

1.1 oration principle

When oil presses operating prepared material enters extruding chamber from the hopper and then moves forwards by the rotating pressing screw and is pressed. Under the high-pressure condition in the chamber ,friction between material and screw ,between material and chamber will be created ,which also creates friction and relative movement among material particles. On the other hand, root diameter of the pressing screw caries larger from one end to the other ,hence. When rotating ,it not only pushes particles moving forwards but turns them outwards as well ,meanwhile ,particles adjacent the screw will rotation along with screw’ rotating ,causing every particle inside the chamber to possess different speed. Therefore relative movement among particle creates heat which is necessary during manufacturing because of helping protein change property ,damage colloid ,increase plasticity ,decrease oil’s elasticity ,resulting in high oil productivity.

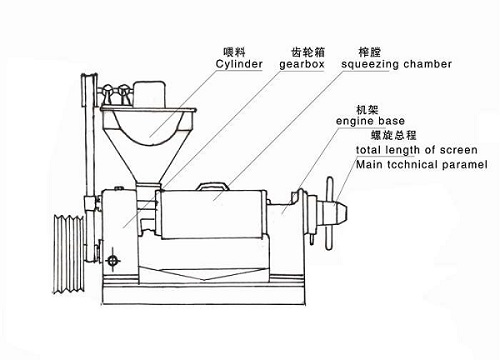

2.結(jié)構(gòu):該機(jī)有進(jìn)料斗部分,齒輪箱部分,榨膛部分,榨螺部分,機(jī)架部分共五大部分組成:見(jiàn)圖

(一)

圖(一)

二.機(jī)器的安裝:

榨油機(jī)安裝時(shí)必須在地腳螺栓牢固的安裝基礎(chǔ)上,使機(jī)體保持水平。電機(jī)安在進(jìn)料斗的背面。

2.Installment

The oil press must be installed by bolts firmly on the foundation and be kept horizontal

三.機(jī)器的潤(rùn)滑:

1.榨油機(jī)主要采用機(jī)油和黃油兩種形式潤(rùn)滑。加油周期見(jiàn)表二

序號(hào) NO | 潤(rùn)滑部位 lubrication | 油脂種類(lèi) lubricate | 加油周期 Time span | 換油周期 Lubricate replacement period |

1 | 調(diào)節(jié)螺栓 Adjusting bolt | 20號(hào)機(jī)械油 Mechanical oil NO.20 | 每班2次 1-2time/day | |

2 | 傘齒輪 Bevel gear | 20號(hào)機(jī)械油 Mechanical oil NO.20 | 每班2次 1-2time/day | |

3 | 軸承座套 Bearing bush | 20號(hào)機(jī)械油 Mechanical oil NO.20 | 每班2次 1-2time/day | |

4 | 齒輪箱 Gearbox | 20號(hào)機(jī)械油 Mechanical oil NO.20 | 首次加油12kg | 六個(gè)月 |

5 | 各滾動(dòng)軸承 bearing | 潤(rùn)滑油 Grease | 每年一次 |

3. Lubrication

3.1 Oil press is lubricated by lubricating oil and grease, see table(2)

四.機(jī)器操作:

(一)開(kāi)機(jī)前的要點(diǎn):

1.開(kāi)機(jī)前先將齒輪箱內(nèi)加注12公斤機(jī)油.

2機(jī)器安裝好后,按規(guī)定加注潤(rùn)滑油,檢查各零部件是否緊固,操作手柄,插板是否靈活.

3.用手搬動(dòng)大皮帶輪查機(jī)器有無(wú)松動(dòng)或卡機(jī)現(xiàn)象,若有異常及時(shí)排除.

4.調(diào)整皮帶的松緊度,啟動(dòng)電機(jī),檢查槽輪方向是否與標(biāo)志方向一致.

5檢查準(zhǔn)備工作做好后,松開(kāi)緊鎖螺母把榨螺擰到死點(diǎn),再退回3-4圈,再前進(jìn)半圈,保證榨螺與出餅口的間隙.

4.1 preparations before operating

4.1.1 12kg of lubricant needs to be filled into the gearbox.

4.1.2 After installing the machine, check whether lubricant has been filled in, bolts have been tightened, and handles are operable.

4.1.3 Check large pulley whether it is loose or blocked, repair it if necessary.

4.1.4 Adjust the tightness of the belt, switch on the motor and check its rotation direction.

4.1.5 Loosen the lock nut and tighten the screw to its end, then loose it for3-4circles and then tighten it again for half circle to assure the gap of the residue cake outlet.

(二)開(kāi)機(jī):

1、啟動(dòng)電機(jī),開(kāi)動(dòng)機(jī)器,將餅加入6%-8%水分,倒入料斗,磨光榨膛,進(jìn)料不可過(guò)猛,否則可能造成榨膛堵塞與卡死機(jī)器事故,因此開(kāi)始下料應(yīng)該緩慢均勻,待榨膛磨光后,正常出餅后,方可將料胚倒入料斗.

2.運(yùn)轉(zhuǎn)后觀察出餅情況,如不出餅,將榨螺再退出1-2圈,如還不出餅,應(yīng)停機(jī)檢查.切記杜絕開(kāi)帶車(chē).故障排除后再行初榨工作.正常運(yùn)轉(zhuǎn)時(shí)餅厚1-2毫米,餅成瓦片狀,手捏不粘,內(nèi)面光滑,外面發(fā)皺,表面不帶油跡.

餅厚的調(diào)節(jié):搬動(dòng)調(diào)節(jié)螺旋上的手柄,將調(diào)節(jié)螺栓順時(shí)針旋轉(zhuǎn),螺栓往外,餅就厚,反之餅就薄了。(調(diào)節(jié)螺栓為左T165x6)出餅圈與出渣稍頭的錐角不同,每轉(zhuǎn)一圈較餅厚度變化為0.4-0.5毫米。

3.榨油機(jī)運(yùn)轉(zhuǎn)中,應(yīng)經(jīng)常檢查出油,出渣情況,正常時(shí)油大部分從條排與前幾節(jié)園排流出。如餅碎成渣,說(shuō)明胚料太干。如發(fā)現(xiàn)餅發(fā)熱(散出蒸汽)成大片狀說(shuō)明水分太高,應(yīng)及時(shí)進(jìn)行調(diào)節(jié)胚料水分的含量。

出渣:條排出渣時(shí)成細(xì)片狀說(shuō)明水分高,如出粉狀含沫說(shuō)明水分低。園排渣過(guò)多屬壓緊螺母未壓緊圓排,應(yīng)上緊壓緊螺母,如水分合適,則條排不出渣或少出渣,圓排少量出渣也是允許的。料胚含水分的高低直接影響出油率,因此壓榨時(shí)應(yīng)控制好料胚的水分。

4.2 Operating

4.2.1 Feeding must be steady and slow at the beginning to avoid blocking

4.2.2 In the case no cake is extrude outward,return back the screw for 1-2circle 。If there is still no cake is observed,machine needs to be shut down and checked ,However, in any case, operating the machine backward is absolutely prohibited normally ,cake looks like tile but not sticky ;thickness is 1-2mm ,inner side is smooth ,out side creases and no oil the surface is allowed.

Cake thickness adjustment: Rotating the adjusting handle clockwise will make the cake thicker, otherwise will make it thinner. Each circle of adjustment (by adjustment bolt left hand T 165x6)will change the thickness 0.4-0.5mm.

4.2.3 When machine is operating, oil extruding and residue outlet need be checked

Frequently .Normally, most of oil will flow outward from square rods and several front round plates. Broken cake residue indicates the material is too dry; steam emerging from the cake residue indicates that it is too wet; In any case, water content in the raw material must be adjusted from time to time.

Slag slice emerging indicates too much water content and power-like slag low water content .Loose round plates will cause too much slag flowing outwards. However, adequate water content will cause slag flowing outwards from square rods; little slag from round plates is allowed. In a word, water content affects oil output rate, it needs adjusting properly.

(三)停機(jī): Stopping

1.正常停機(jī)應(yīng)將料胚全部榨彎,反復(fù)將榨螺退進(jìn)數(shù)次,將榨膛中語(yǔ)料 走完,將出餅放至最后,然后停車(chē).

2.停電或因其它事故突然停車(chē),先切斷電源,抽出放料擋板, 用人力反轉(zhuǎn)大皮帶輪,使心軸反轉(zhuǎn)時(shí)退出料胚,立即將榨螺軸推出榨膛(當(dāng)人力反轉(zhuǎn)大輪困難時(shí),不得強(qiáng)制進(jìn)行.以免損壞機(jī)器),進(jìn)行清理.若抽不出來(lái),應(yīng)將壓榨螺母松動(dòng),要把上榨籠拆釣,用螺絲刀逐個(gè)將圓排松動(dòng),清理,未經(jīng)清理不得再行開(kāi)車(chē).

4.3 stopping

4.3.1 Repeatedly move screw forwards and backwards for several times and let all material resided in the chamber goes out and adjust the cake to the possible thinnest, then stop the machine.

4.3.2 When machine stops caused by any accident, power supply must be shut down first, then rotate large pulley manually backwards, let the material return out. Then pull out the shaft and clean it. In the case the shaft could not be pulled out, remove the upper case and loose lock nut, separate round plates and clean them one by one.

五.機(jī)器的主要零部件拆,裝:

1.主要零部件的拆裝方法:

(!)榨籠(包括圓排、條排骨圈)的拆裝方法:

旋轉(zhuǎn)榨螺軸,將榨螺 從榨膛內(nèi)抽出,然后用直徑24毫米粗的鐵棒插入出餅端壓緊螺母的孔內(nèi),逆時(shí)針?lè)较蛐D(zhuǎn)松動(dòng)螺母:松動(dòng)上榨籠兩端4個(gè)M16的連結(jié)螺釘,卸掉連結(jié)上下榨籠的12個(gè)M16的螺栓,拆去上榨籠即可將圓排圈取出。

(2)條排的拆裝方法:

卸下條排骨圈用鐵棒的一端從側(cè)面抵住一根條排,用手敲擊另一端,將一根條排打出,其余條排將自動(dòng)松散下來(lái).

(3)條排的裝配方法:

將條排圈立起,代出油槽面向下(建議下面放塊木板),把條排逐個(gè)的整齊的排列在內(nèi)壁上。帶深油槽的一端朝下,兩個(gè)條排的深油槽面不能對(duì)著放在一起。最后一個(gè)條排用金屬棒打入》若條排松動(dòng),可以在條排之間加鐵皮,使條排緊貼內(nèi)壁,達(dá)到用手摸內(nèi)壁無(wú)突起現(xiàn)象為止。

(4)榨籠的裝法:

將條排圈有出油槽面面向機(jī)架,再按圓排序號(hào)依次放入圓排。帶出油槽面朝向機(jī)架。然后用壓緊螺母少上幾扣靠住圓排,在裝上榨籠。(上下榨籠均為配對(duì)制造,如更換需上下一齊換掉)用卸下的螺栓逐個(gè)交替上緊。

5. Maintenance and Assembly/disassembly of Main parts

5.1 Assembly/disassembly of Main parts

5.1.1 Pressing cage (round plates, square rods holder)

Rotate the screw shaft and remove it from the chamber. Loose the lock nut on the outlet end by rotating it counter-clock wise using a 24 mm diameter bar, loose four M14bolts, remove ten M16 bolts which are used to connect upper and lower cases. However, after removing upper case, round plates and square rods holder can be pulled out.

5.1.2 Remove square rods:

After removing the holder, tap the end of one rod and take it out, then others will be easily removed.

5.1.3 Assembly of rods:

Erect the rod holder vertically and make its side with oil grooves locate downwards, better on a wooden plate, then put square rods to touch holders inner wall circumferentially with their grooves downwards again. However, grooves of every two adjacent rods should not be touched. Then insert shins (by a hammer) properly into rods gap to let than firmly touch rods holders inner wall. As a matter of fact, whole inner wall of rods should be smooth.

5.1.4 Assembly of the cage:

Put the groove side of rod the holder to face the machine body, and then insert round plates as per marks on them. Put lock nuts on to contact plates and then mount the upper case. Tighten bolts one by one.

備案號(hào):豫ICP備2021014171號(hào)-3